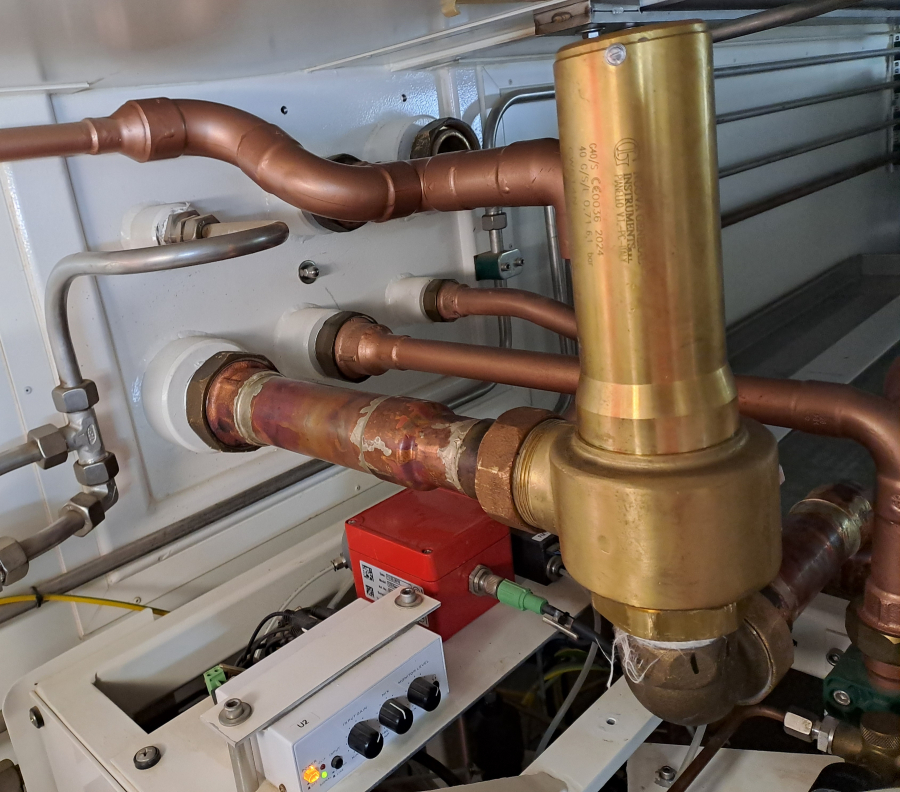

Safety relief valves play a vital role in co-generation and biogas systems, where flammable gases and potentially explosive atmospheres demand the highest level of protection and reliability. Our models include G14/S (PN 60), G20/S (PN 60), E10/LS (PN 100), and E8/LS (PN 300), available in sizes DN10 to DN40 with piped discharge and pressure ratings from PN40 to PN600.

Made from Brass and SS316L stainless steel, these valves are designed to prevent static charge buildup, gas leakage, and overheating. These features are critical for systems operating in ATEX-classified zones, where the generation of mechanical sparks during valve operation must be avoided.

ATEX Compliance and Safety Design:

Our valves can be provided with ATEX certification, making them suitable for Zones 1, 2 (gas) and 21, 22 (dust). In applications involving hazardous gases, the shutter’s movement during full opening can cause mechanical friction and sparks. To mitigate these risks, the materials and geometry of our valves are optimized to ensure spark-free operation and maximum containment.

Certifications and Standards:

Our safety valves for cogeneration and biogas plants comply with international standards, including:

- • ASME Certification: Ensures that the valve design, materials, and manufacturing processes meet strict global quality and safety requirements. This is critical for high-pressure, high-risk environments.

- • ATEX Certification: Guarantees that the valve can safely operate in explosive atmospheres by reducing ignition risks caused by friction, heat, or static electricity.

These certifications not only affirm safety and reliability but also offer assurance during inspections, audits, and integration into regulated industrial environments. Our valves help minimize the risk of failure, protect plant infrastructure, and ensure uninterrupted operation even in the most demanding biogas and cogeneration setups.